Committed To Quality, Committed To You

SIVTEK® Roto Sifter from the house of Galaxy Sivtek is one of the most adaptable screening machines across various mainstream industries like the food industry, the pharmaceutical industry, the chemical, dyes & pigments industry, the plastic industry & many more. Before we extract the points, it is quite important to know how our Centrifugal Sifter works.

The material is catered into the material inlet & rechanneled into the sifting chamber with the help of the fed screw. The helical paddles located in the cambers continuously rotate, which results in pushing material forward of material against the screen. Along with the process, the centrifugal force helps the material particles to move faster towards the openings. The process continues with the ejection of oversized particles from the oversized outlet & undersized particles from the undersized outlet.

Adding on to the benefits of the Centrifugal Roto Sifter, the rotating paddles that never come in touch with the screen break the soft lumps.

Experts from the industry always advise us to use our reliable & ideal Centrifugal Sifter for sieving & checking to screen applications like spices, detergent powder, talc powder, quartz powder, milk powder, food additives, chemical powder, lactose powder, sulfate, & many more.

One of the very first reasons why centrifugal sifters are a boom for the pharmaceutical, food, & beverage industries is their compact, dust-free, & hygienic design. SIVTEK® Roto Sifter is designed in a way where the chances of contamination are almost null. It is designed to give much higher throughput for various process industries with the prime benefit of providing a dust-free environment.

Product experts & designers, before designing the centrifugal sifter, had certainly looked after all the guidelines & rules of major governing bodies like the US FDA. Compared to conventional sifters, the SIVTEK® Roto sifter is quiet & works on the no-vibration principle. The noise of the sifter is very minimal, & to be precise, the noise level is less than 80 DB.

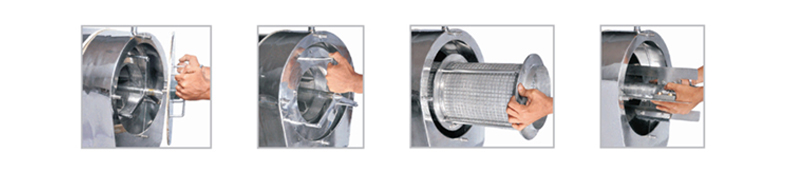

Keeping the separation fundamentals intact, the Centrifugal Sifter enables the screen to change faster than any other separator & sifter ever. The silk & smart design of this sifter can let you change the screen in less than 2 minutes.

The functional Centrifugal Sifter has smoothened the process of cleaning the mesh and basket, and with us, it has been more convenient and easier. SIVTEK® Roto sifter comes with three cleaning options.

Apart from these 4 unexcelled points, there is a lot more that makes the SIVTEK® Roto Sifter a special & unique sieving & separating machine. Here are a few more points that will make sure using & installing Centrifugal Sifter in our plant would be the most capitalizing & wise decision.

Easy to clean: The internals of the sifter can be removed quickly & without the use of tools. This enables easy & quick cleaning.

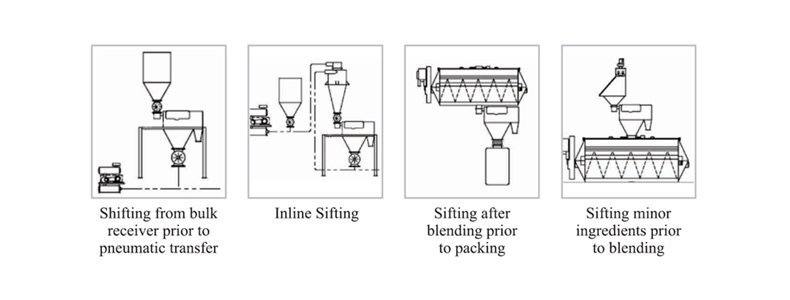

Fits into your current production lines:

To inquire about the machine please get in touch & to know in detail download the e-broacher here.