Committed To Quality, Committed To You

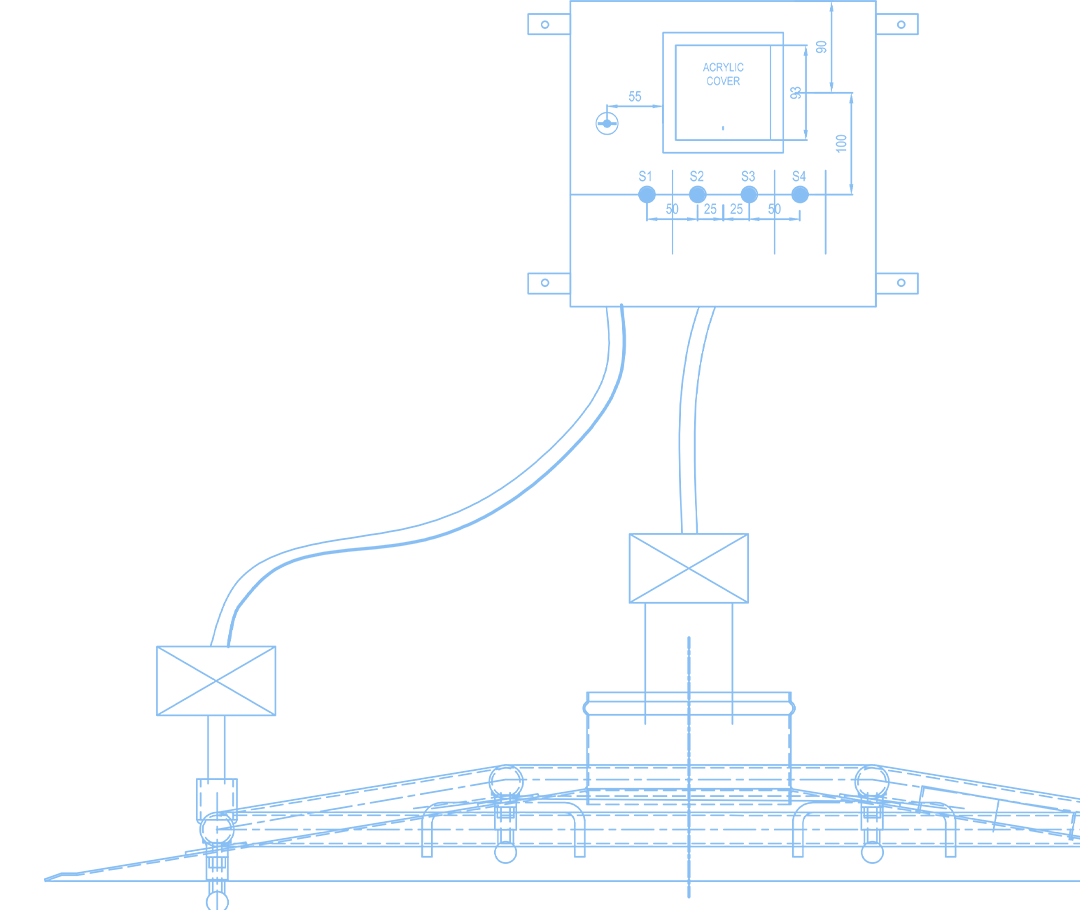

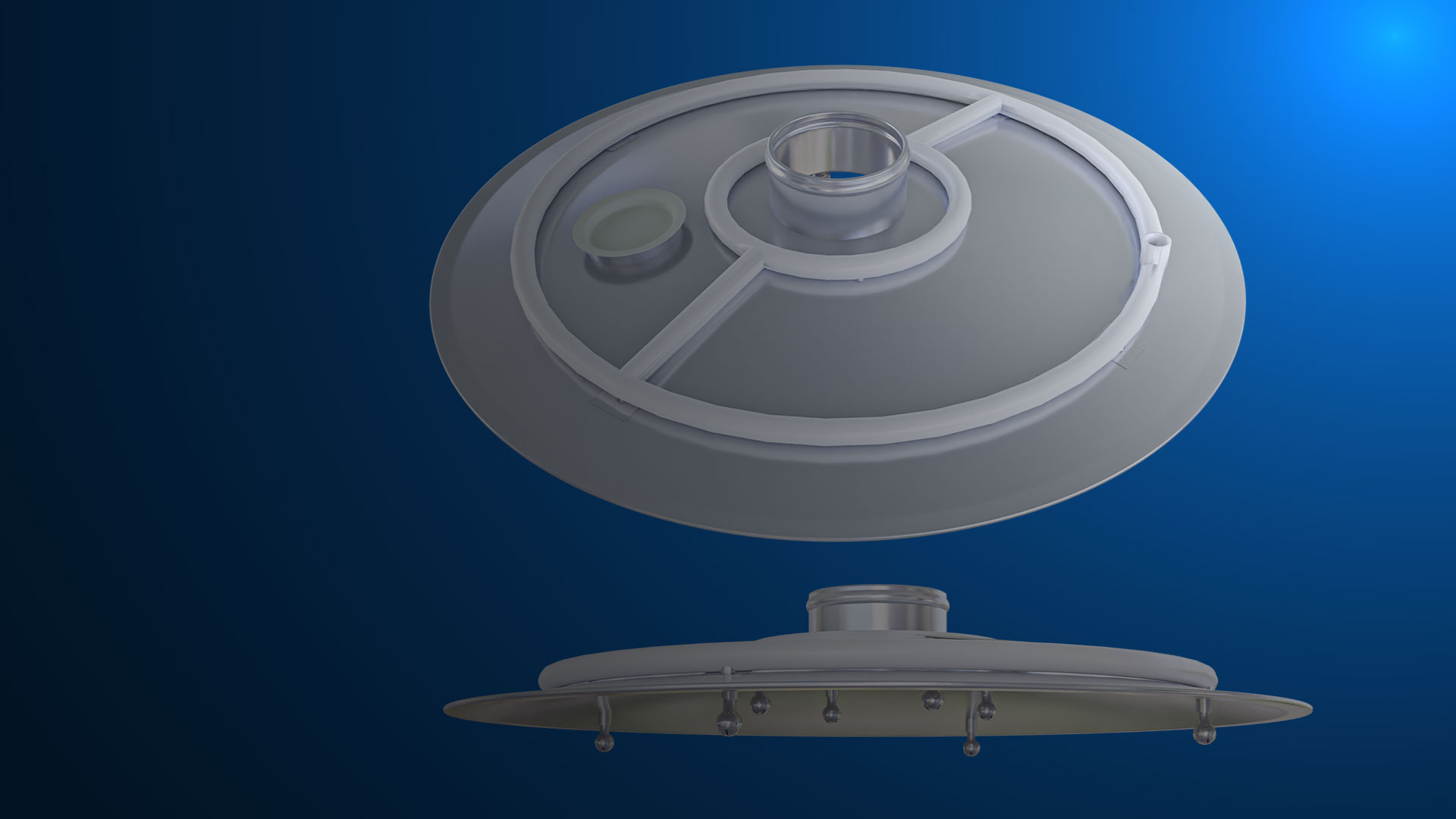

Clean in place is a method of automated cleaning the interior surface of the vibro screen and filters and associated fittings. The CIP is used for cleaning, unclogging, de lumping of the mesh screen or the related fittings. Without the CIP system the cleaning of the closed system was done manually causing a lot of delay and manpower in the process, this is also not cost effective as the production line must be stopped for the cleaning purpose causing delays.

The process of cleaning can be carried out by various methods such as air cleaning, pressurized hot water, chemicals, solvents, etc. these solutions are used not only for cleaning the mesh screen, but also for unclogging the mesh screen.

The CIP is a boon to industries that need frequent internal cleaning of their processes. The industries that rely heavily on the CIP are those that require high levels of hygiene and include dairy, beverage, brewing, processed foods, pharmaceutical and cosmetics.

Various cleaning agents are used for the process of cleaning, unclogging and deblinding of the mesh screen. The entire process of cleaning is done with pressure pumps forcing the cleaning agent onto the SS 304 to 316L nozzles which spray the liquid with pressure. The working and timing of the cleaning process can be done manually and automatic, depending upon the requirement.

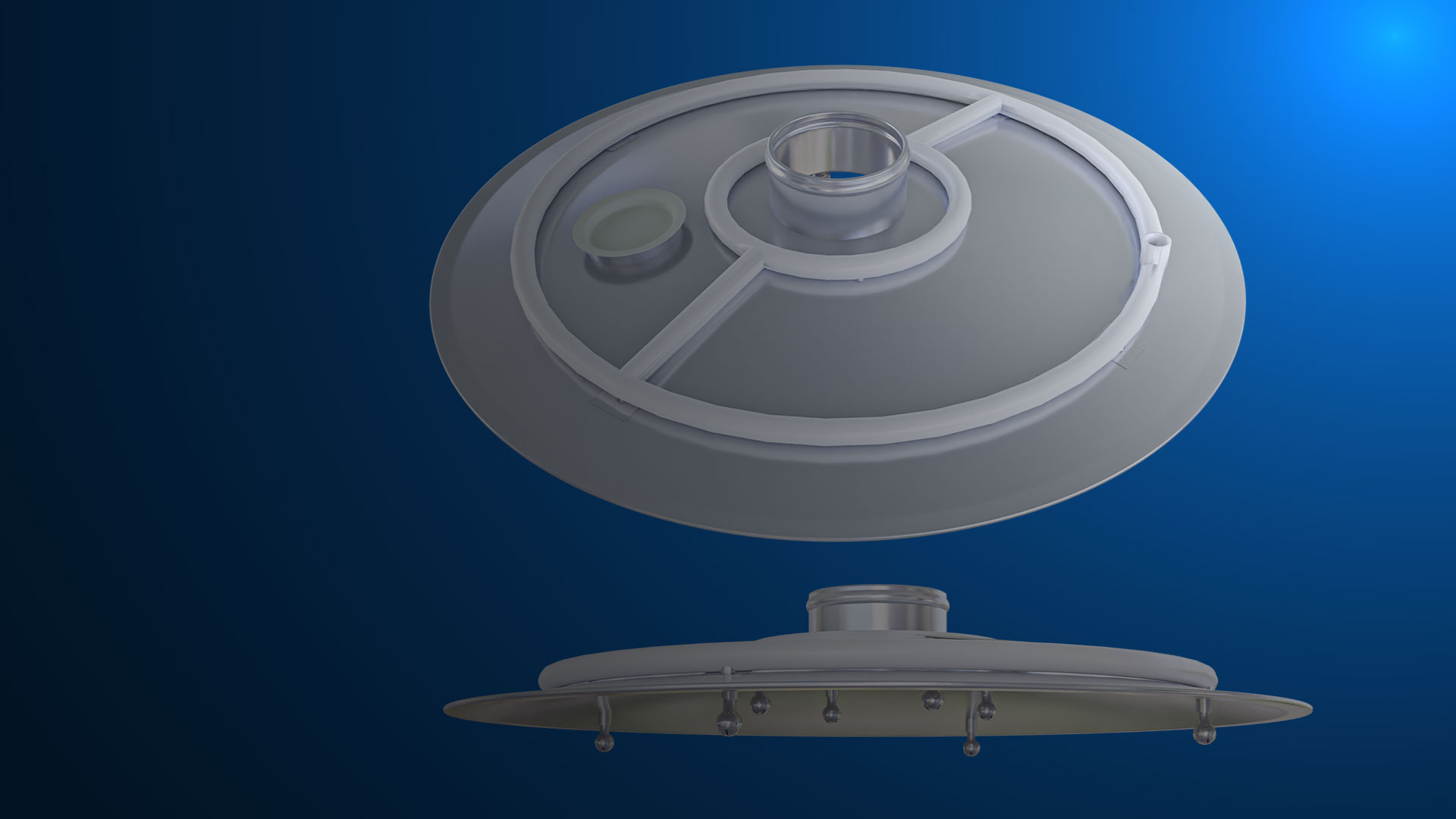

The entire system is enclosed, eliminating the time taken and labour requirement for cleaning manually.

The system once acquired can work automatically causing ease of operation for the operator.

Not only does it cleans the mesh screen, but also unclogs the screen improving the throughput and efficiency.

The entire system is compliant for internal safety and hygienic standards.