Committed To Quality, Committed To You

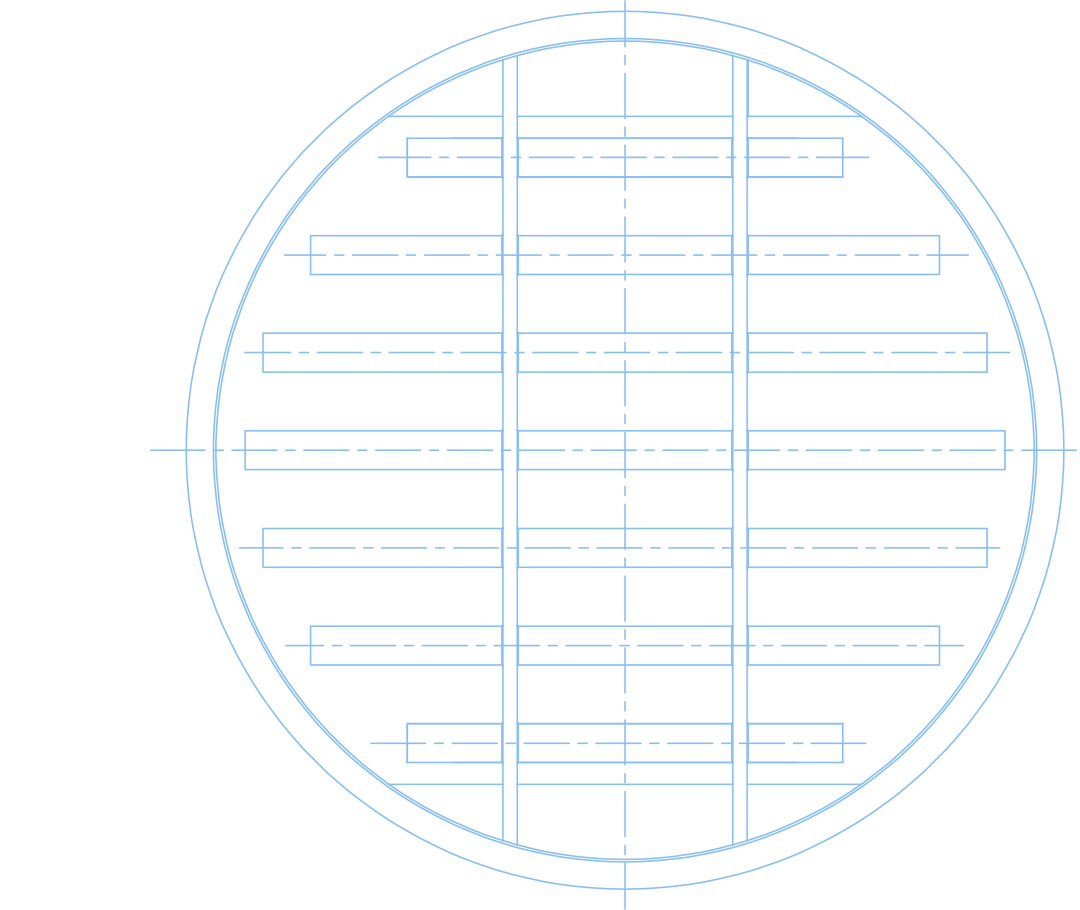

Galaxy Sivtek offers various solutions for removing ferrous contaminants from the processing material, to maintain the hygiene standards these stainless-steel magnets provide high intensity, high gradient field. These magnets are also available in various shapes and sizes depending upon the requirement and the specific dimensions.

The magnets are used especially below hoppers, catch bins, floor openings and fitted inside any requested size frame. Depending upon the material and strength necessary for the material, these magnets are used for check screening for pre and post screening.

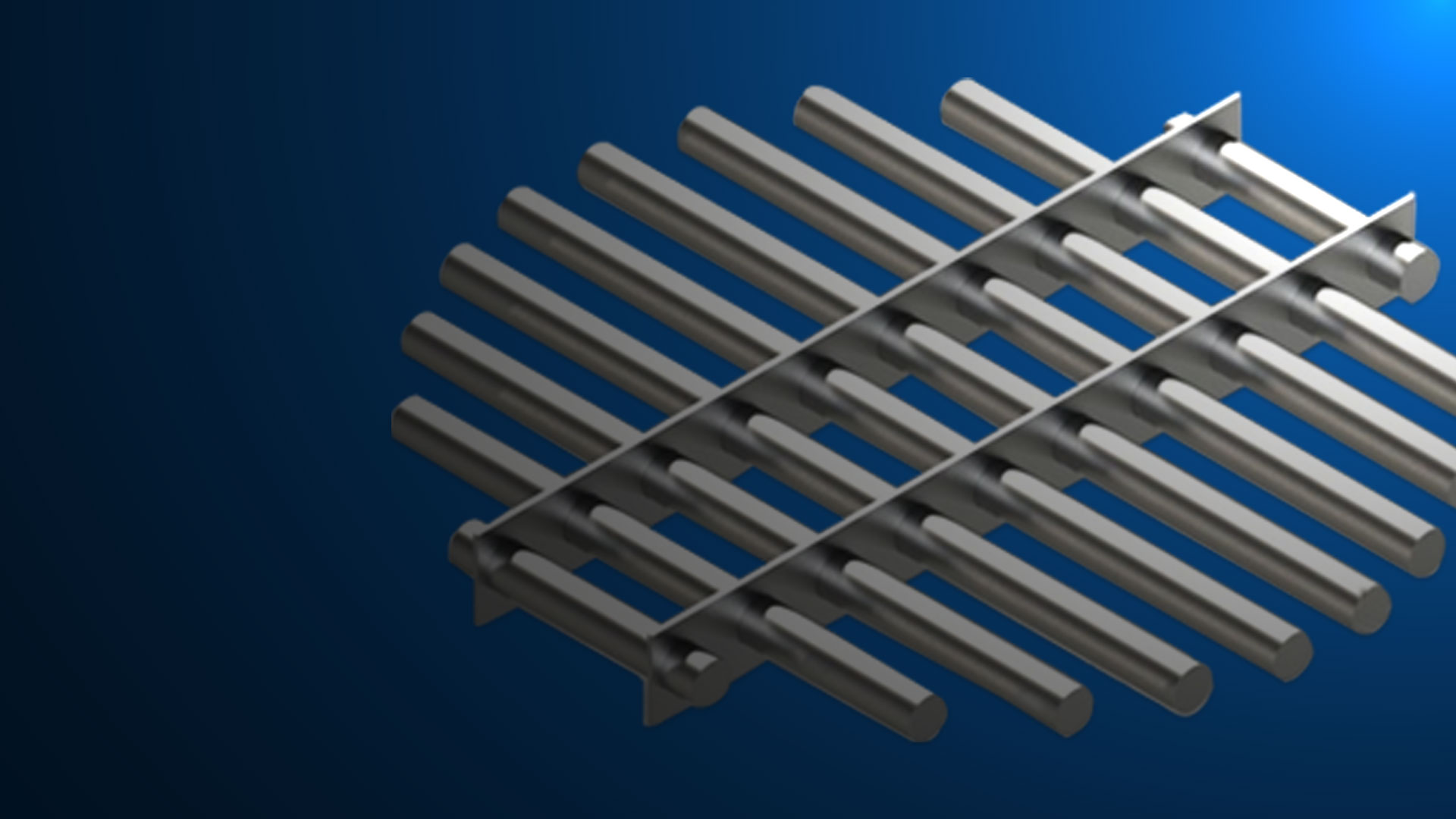

While processing of any material the magnetic grills or magnets can be used at different stages of the process when the material passes through the magnets the ferrous contaminants remain stuck to the magnets and the rest of the required material fall off and move ahead in the process.

The material checks screened, not compromising with the quality.

All heavy ferrous particles like screw’s nuts and bolts may damage the mesh screen resulting in delays and missed commitments, these magnets help reduce those.

We can go up to 12000 gauss of magnetic intensity.

These magnets can work in temperatures up to 350° C.