Committed To Quality, Committed To You

Modern flour processing now has to cater to the demands of efficiency, hygiene, and precision. At Galaxy Sivtek, an integrated service of this very modern need can be attained where advancement in equipment comes in conjunction with smart process requirements so much in demand from a modern flour processing unit. Full automation will get flour dusting very under control, even to the extent of precision at weighing. What more could anyone want or need?

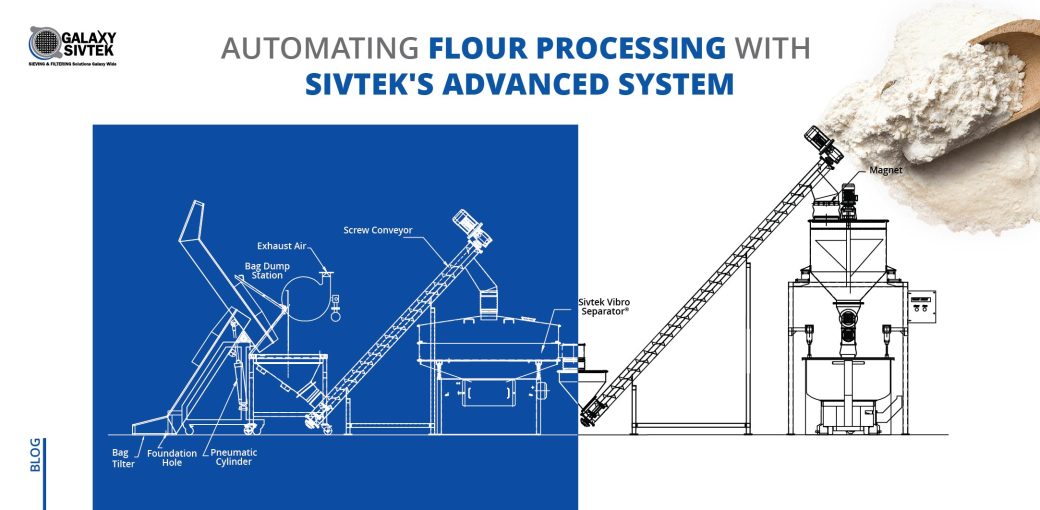

The process begins by first tipping the flour into the receiving bag dump station. The station is very efficiently designed with a dust collection system to capture and hold the flour dust while tipping, ensuring that the working place for the workers is clean and safe.

After the dumping, the screw conveyor feeds the flour into the Sivtek Vibro Separator. It is an advanced separator for screening the impurities in flour and oversized material to provide the product with complete consistency and quality standards ready for further processing.

The sieved flour is then conveyed via a second screw conveyor into another weighing hopper, but this time it will get its accurate measurement that’s taken with precision as taken into the next procedures involved in processing.

After sifting, the flour is released into the mixing hopper as per the weight requirement set. This way, the exact amount of flour needed is obtained to be mixed or further processed for consistency and quality.

This equipment will be perfectly suitable in any flour mills, food processing units, and other kinds of industries requiring efficiency, hygiene, and precision.

Galaxy Sivtek brings decades of expertise in sieving and filtration solutions. This fully automated system reflects the company’s dedication to innovation, quality, and customer satisfaction, offering end-to-end solutions for efficient material handling.

The Galaxy Sivtek automatic flour processing system has now turned into an idol for industries to rise and increase their productivity, keeping quality at superior levels. Be it dust control or precision weighing, the system tackles it with ease.

Contact Galaxy Sivtek today for further details of how this advanced system will elevate your flour processing operation to new heights.