Assisting Automobile Industry with Sieving & Filtering Solutions

Overview

Automobile industry is the fastest growing industry in the modern world. Engineers and designers are working non-stop to develop robust and reliable marvels. They need to provide quality in every part and structure they manufacture to meet the safety, comfort, strength, finish, and performance requirements.

Abrasive blasting or sandblasting is one of the processes involved in automobile manufacturing to smooth a rough surface, coating and removing surface contamination. This will improve the strength and finish of the blasting material.

Automobile industries are using small steel balls as Abrasive blasting materials. Once used, these balls are reclaimed from the blasting booth and used again. One of the leaders in the automobile industry was facing some issues with reclaiming the material and they wanted a reliable solution to it. Let’s see what was the exact problem & how they overcome this problem.

Requirement & Challenges

Steel balls once used cannot be reused again for blasting! Just because after blasting on the metal surface the size of the steel ball changes and you cannot use the uneven size of steel balls for the blasting process. Uneven size of balls can affect the quality of the final product. They had to buy a new batch of steel balls which ultimately increases the cost to the company.

They wanted to reduce the cost of steel balls and wanted some legit solution to reuse the material. They wanted a solution that can provide them the reusable steel balls out of the small size steel balls and remove dust and other unwanted impurities. Days gone! and the problem remains the same. They tried every aspect they could, but all in vain. Finally, they come to know about Galaxy Sivtek.

Solution

Galaxy Sivtek is the leader in Sieving & Filtering solutions since 1990. They are committed to providing you with quality and long-term solutions that you can rely on. The management team from the automobile industry explained the whole situation and described the pain they were suffering from.

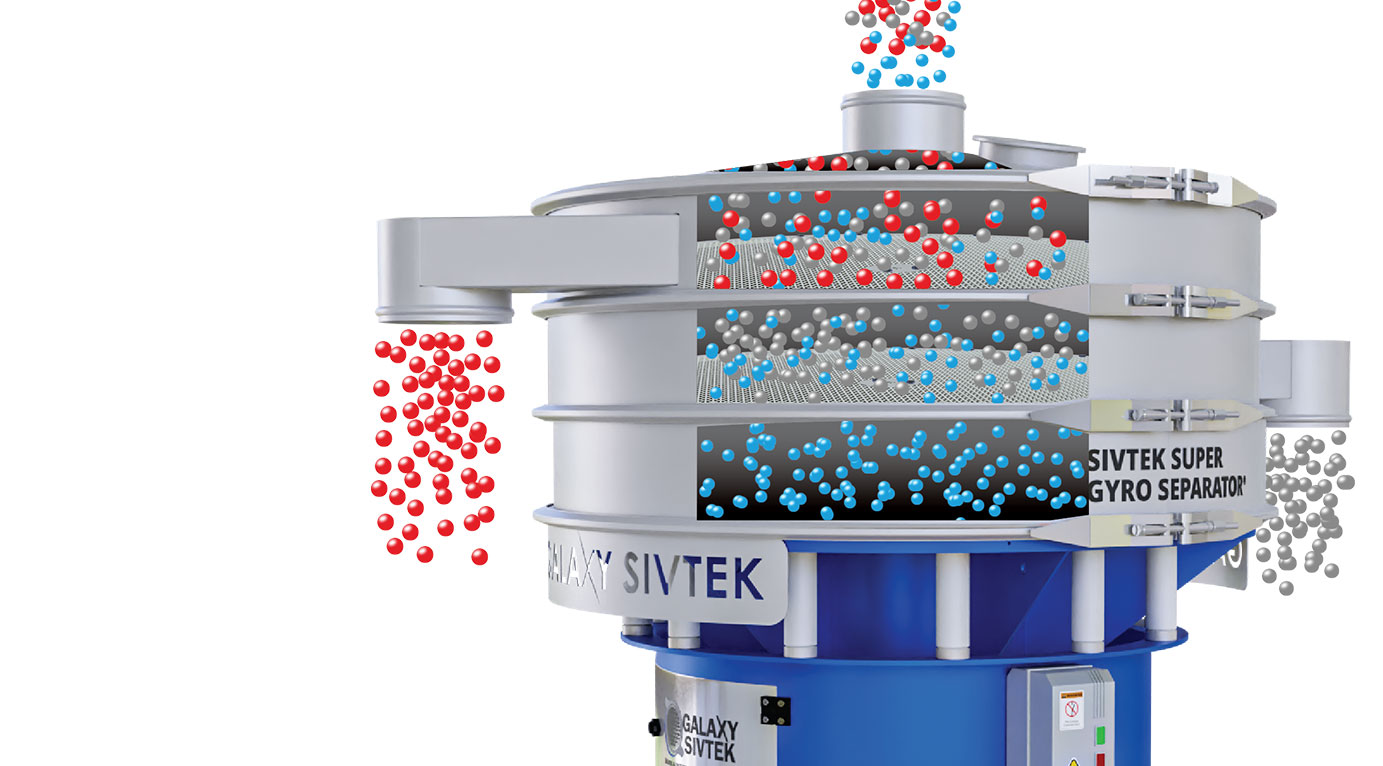

Galaxy Sivtek thoroughly examined the situation at client site and observed that this problem can be easily resolved with proper sieving equipment. The Sieving expert took the steel balls sample to the trial facility of Galaxy Sivtek and put the trial on SIVTEK Vibro Separator which is considered to be the best equipment for grading this material.

A number of trials were performed to meet the capacity and proper screening of the product. Sieving expert suggested using the SIVTEK Vibro Separator of size 40” to get the desired results.

The plant manager also demands an arrangement that allows the worker to easily pour a bag of steel balls on the sifter which was quite high from the ground. Galaxy Sivtek design team customized the sifter with a hopper which allows the worker to easily pour the bag and stairs to reach that height.

They procured the machine as suggested by the sieving expert. The design team also claimed that the machine is enclosed so that there is no chance of dusting as well. Due to this arrangement, the machine has eliminated the requirement for more workers and automated the system.

After few weeks the analysis team went to measure the performance of the sifter and the durability of the solution. The managing director concludes that “We have saved a lot of our valuable resources with this system. Our cost of buying steel balls has reduced drastically and now! our ROI percentage is quite high increasing the profitability, just because of Galaxy Sivtek. We are soon going to cover our investment also which was made on purchasing the sieving machine.”

According to the plant manager, there is no rundown because of the sieving process and the customized system has made the screening process very easy for them. “We have also ordered 4 more systems at our other plants to achieve the same results.” said the manager.

The Sieving solution was able to provide high throughput and accurate quality of steel balls from which they can reuse the desired size for the abrasive blasting process.