How SIVTEK Roto Sifter Assisted the Dextrin Manufacturer to Increase Profitability

Overview

Dextrin is in the form of carbohydrates having very low molecular weight. Dextrin is produced by the hydrolysis of starch. Dextrin is soluble in water and comes in white, yellow, and brown powder.

You must have heard about the British gum which is nothing but the yellow and white dextrin. Dextrin is used in diversified industries. It is used in food processing in food batters and coating. Coating agent for textile industry, thickening and binding agent in pharmaceutical and paper industry, chemical, agriculture, firecracker, and many more industries.

One of our clients is the manufacturer of dextrin powder. They were facing a few difficulties in the manufacturing process and finding a robust solution to survive in the competitive market. Let us see how Galaxy Sivtek has helped the manufacturer to get rid of their sieving problems and increase their profitability.

Requirement & Challenges

The manufacturing of dextrin powder starts with the roasting of starch mixed with added acids. This procedure changes the chemical and physical properties of the starch and converts it into dextrin powder. Before packaging, they were using two Vibro separators to remove unwanted impurities and remove lumps from the material. The major problem they were struggling with was the dusting issue while sieving. They were using a conventional Vibro separator that creates lots of dust while sieving and because of that lots of material was wasted.

They wanted a dustproof screening solution that can run for a longer time without much maintenance. They also mentioned that they have to use two separators to cope with the production rate.

Solution

Galaxy Sivtek’s team of experts visited the factory and analyzed that the material (Dextrin powder) is of low BD and generates lots of dust while sieving. According to the sieving expert, even if we provide the proper lid and gasket covering the solution will be temporary. But to compete with the competitors they have to opt for a robust sieving solution.

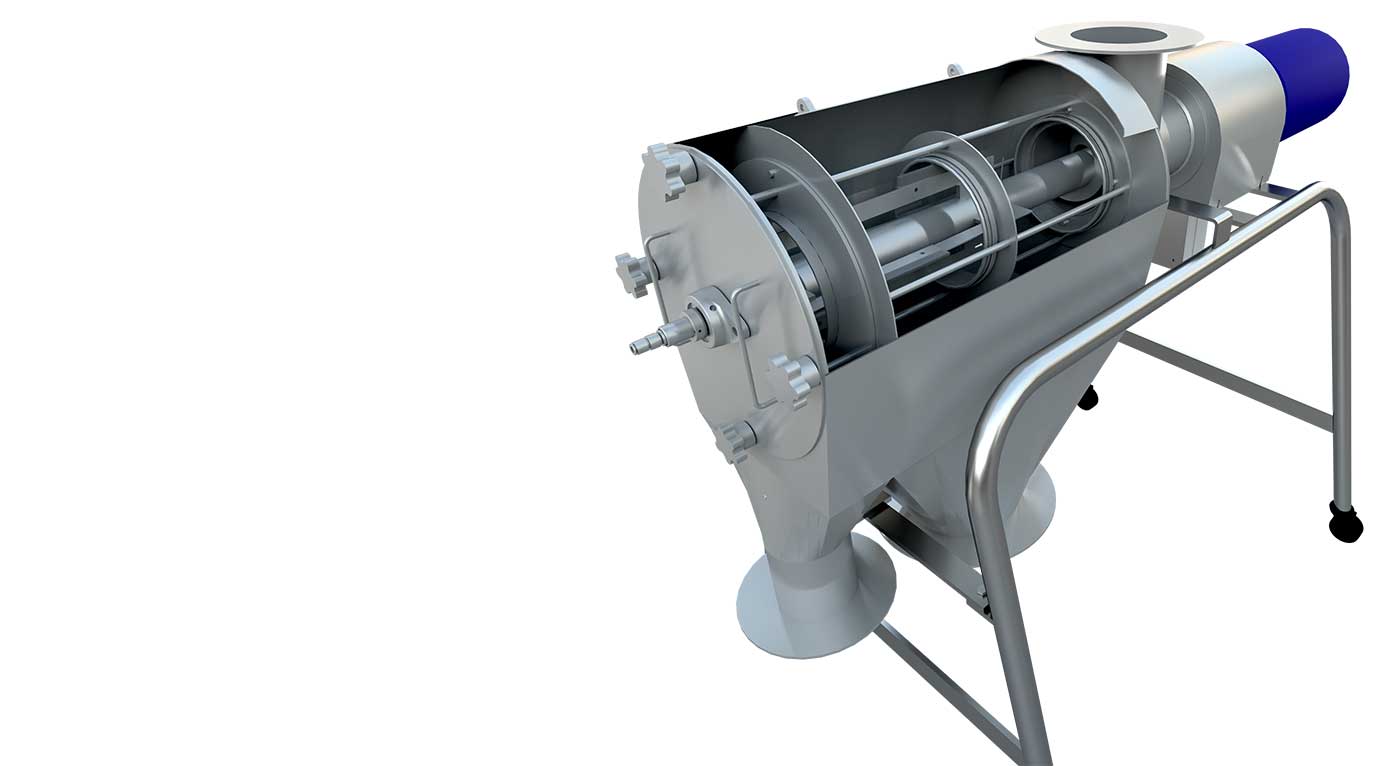

Our expert suggested first going for an enclosed sieving system and switching to a twin roto sifter which is highly effective in this kind of material & environment. The machine will sieve the material in a closed environment and provides a higher throughput capacity due to its twin sieving chambers.

To know more about SIVTEK Twin Roto Sifter Click Here

The expert also suggested they reuse the conventional separator after a few alterations to boost the performance before the roasting process. So that any impurities present earlier can also be removed. So that their existing resource is not wasted.

Results

After a successful installation, the Twin roto sifter was taking lesser space than the two conventional sifters. A few months later when initial reports were taken the plant manager mentioned that “Our dusting issue is completely sorted and wastage is nill. we have seen a drastic increase in our production rate.” The company also increased its profitability and is now planning to increase its production area to better stand in the domestic and export market. Soon they are also planning to replace their old conventional sifter with Galaxy Sivtek’s vibrating equipment.

Galaxy Sivtek is having years of experience in providing proven results for Sifting, Screening, Sieving, Grading, de-dusting & filtering solutions for numerous processing industries’ products & applications. If you are looking for a sieving or filtering solution for your product feel free to get in touch with our experts.