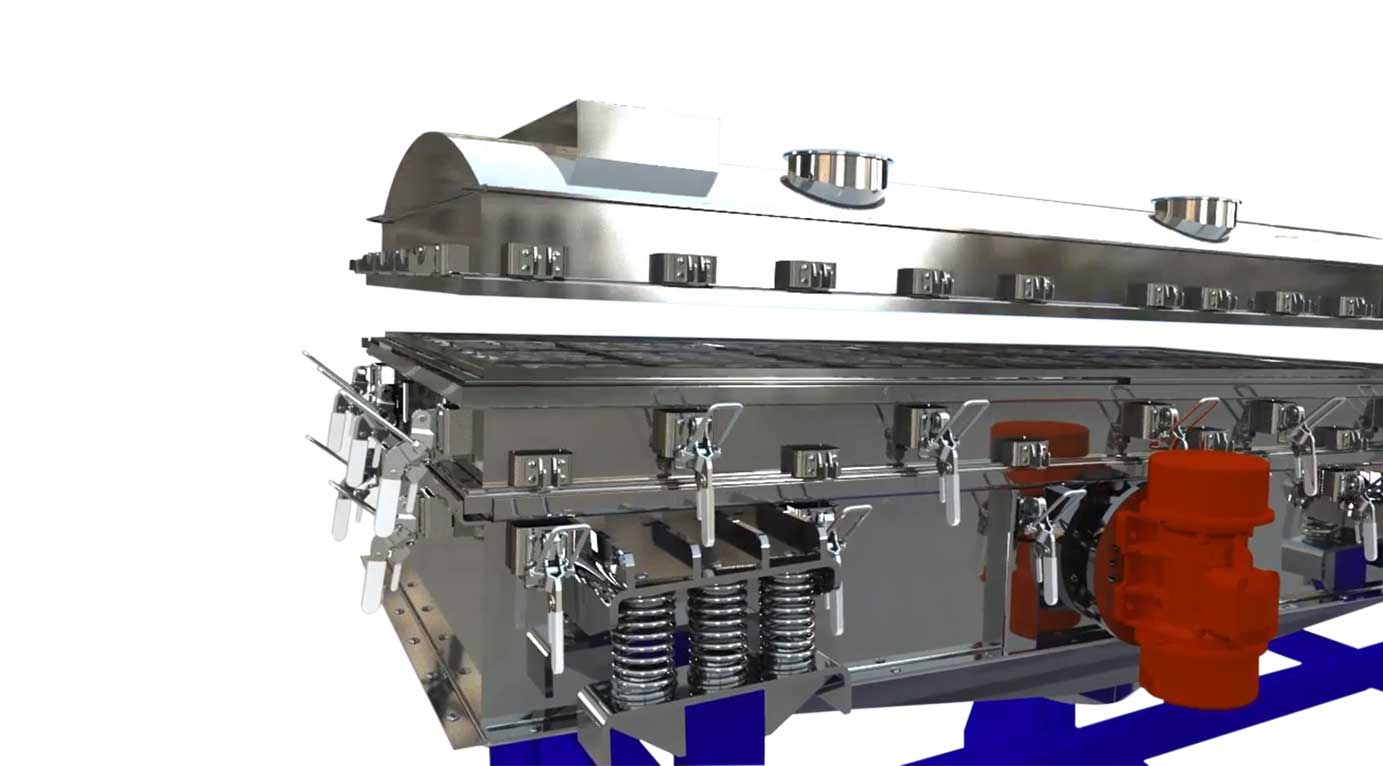

Linea Sivtek® with CIP system for filtration of sugar syrup

Overview

Galaxy Sivtek helped sugar mill in manufacturing high-quality sugar crystals by filtering out fine suspended impurities from sugar syrup before it goes to the centrifugal machine for crystalizing.

The sugar that adds sweetness to our food, beverages & medicines goes through a long process! From crushing sugarcane to drying down sugar crystals it has a wide process.

Our client owned the capacitive Sugar mill in Africa with a plant having the capacity of producing xyz ton sugar per day. They were key producers of commercial grades of white & brown sugar.

The real process of sugar starts from growing & harvesting sugar canes. Sugar canes are then crushed to obtain mixed juice. Mix juice is then passed thru screeners & separators to remove fibres. Mix Juice is then sent to clarifiers to obtain clear juice.

Clear Juice is further evaporated to reduce the water percentage & obtain a thick syrup. Sugar syrup is further bleached with alcohol & sugar crystal to get it in crystallized form. It is further moved to centrifuges (High-Speed Rotating machines) to obtain sugar crystals & crystals are then sent to large dryers where hot air is blown to reduce humidity. Further crystals are cooled down in coolers & before packaging, and crystals are graded as per market standards in multi deck screeners. So that’s how sugar is made!

Requirement & Challenges

An alarming situation occurred when multiple batches of sugar were rejected by the QC department as it was of poor & low quality & did not match ICUMSA standards.

Looking up into the matter it was found that fine suspended impurities in sugar syrup were the reason for the low-quality batches.

Fine suspended impurities & extraneous matters (minute black particles) present in sugar syrup result into thick, more blackish & poor-quality syrup that does not match ICUMSA grade.

The rejected slots had to be reprocessed again with the sugar melting process, the reprocessing increased their overheads including labour, time & cost.

Solution

Efficient & robust filtration machine for removing fine suspended impurities & extraneous matters from sugar syrup.

Quick & easy cleaning arrangement as frequent cleaning between the batches would be required.

The production head of the mill contacted Galaxy Sivtek as he was familiar with our sieving & filtering solutions. Currently, they are using our Vibro Separators for removing bagacillo from raw juice.

The Product sales manager – Africa, suggested them to install a horizontal screener before sugar syrup is sent for crystallizing so all fine suspended impurities & extraneous matters can be removed.

During the conversation Production head of the mill said, “During filtration very fine oversize particles would stick over the mesh & that might block the mesh. We would require an expeditious cleaning system that can help in removing oversized particles with ease.”

After understanding the requirements, we suggested installing Linea Sivtek® along with a Clean in Place (CIP) system & four material distribution inlet pipes on the led.

Linea Sivtek® – The horizontal screening machine was suggested seeing the nature & characteristics of the material to be filtered i.e. sugar syrup.

Clean in Place (CIP) system was given to solve the problem of manually cleaning the screen. Clean in place system is engineered in way that would spray water with spray nozzles inside the screen as & when required.

Without material distribution inlet pipes, sugar syrup will fall on the screen rapidly & at one point only. This might result in tearing of screen & unequal distribution of syrup on screen.

To avoid wear & tear of the screen and for equal distribution of syrup on screen four material distribution inlet pipes were given. Equal distribution enables optimal filtration of the material.

Results

The results were really good as every aspect was taken care of. From cleaning of the screen to equal distribution of sugar syrup on screen, everything was properly designed & engineered that in return gave the exact expected results.