Success Story: Screen Biscuit & Cookie Ingredients.

Overview

SIVTEK Solution Range has Improved Sizing of Biscuit Ingredients which Resulted in High-Quality Biscuits & Cookies.-Global Biscuit Manufacturers.

Requirement & Challenges

Business Case: Screen Biscuit & Cookie Ingredients.

Process Scenario-There are primarily four stages in making the biscuit mixing, forming, baking, and cooling Mixing is crucial in biscuit production and is the first of the four major production steps where all the ingredients are perfectly blended to allow the manufacturers to produce the

perfect biscuit.

Correct Proportions. Before mixing flour, fat, sugar, salt, additives, and other important ingredients in the right proportions for dough mixing, all the ingredients have to be precisely sized to achieve perfect biscuit quality.

The respective production team at different biscuit manufacturers were not satisfied with the sizing quality of the final biscuit ingredients before mixing. After learning about their concerns and requirement for precise sizing of raw materials, we proposed one of the best-performing solutions the SIVTEK Vibrating Sieve to overcome quality challenges.

Similarly, the cream biscuit manufacturers were too not happy with liquid chocolate or other flavored biscuits such as mango, strawberry, vanilla, or more.

Concerns: Sizing Quality of Biscuit & Cookie Ingredients and Cream Quality.

Solution

National Sales Manager, Galaxy Sivtek India, shares that “After meeting fortune 500 biscuit & cookie manufacturers and visiting their respective production units, the production heads cited that, before mixing the quality sizing of biscuit ingredients is the major concern for low-quality biscuits OR rejection of batches of biscuits, which eventually leads to increase in the production cost. Also, the biscuit manufacturers faced a concern of the low-quality chocolate, mango, vanilla, strawberry, or any other flavored cream used in manufacturing various cream biscuits, concludes, NSM, Galaxy Sivtek India.

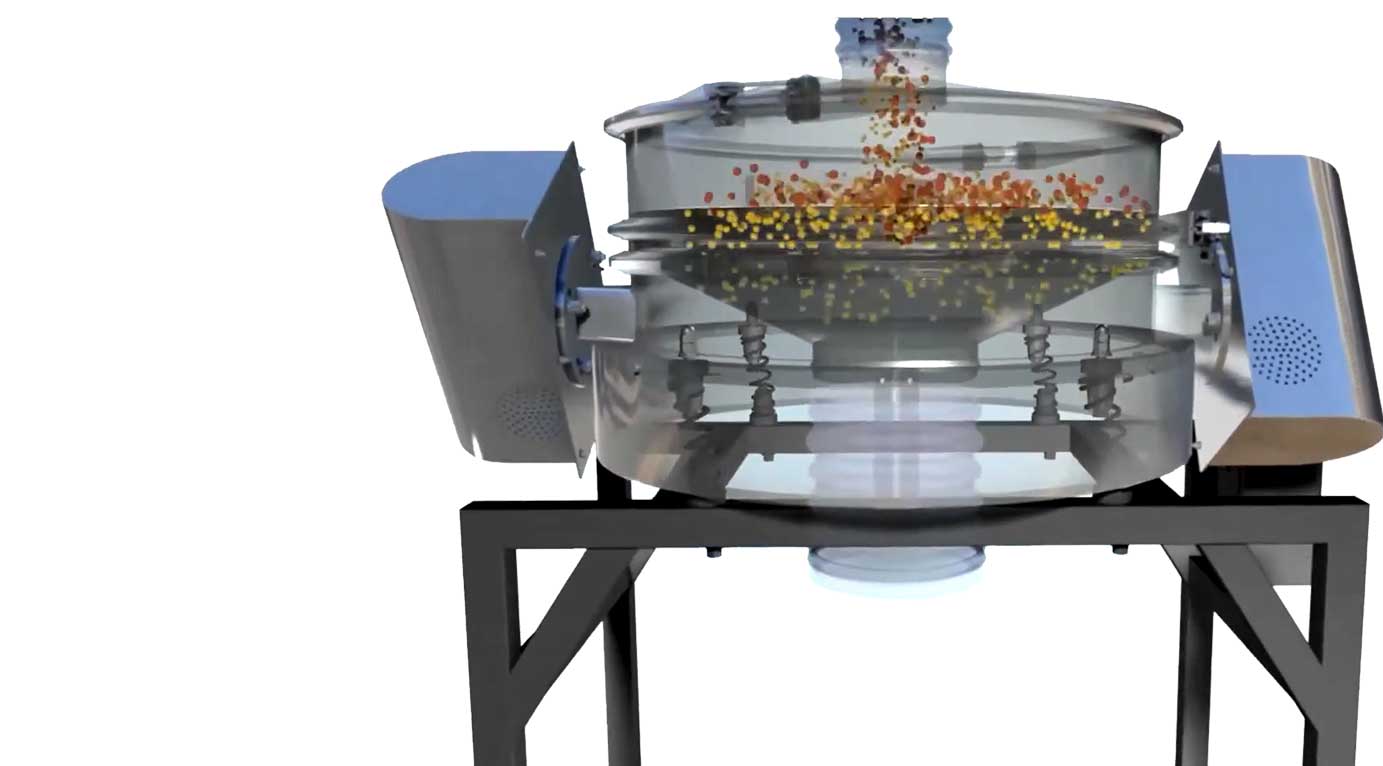

SIVTEK solution namely the SIVTEK Vibrating Sieve series and SIVTEK Self Cleaning Filter is specially engineered to precisely size raw materials and improve the quality of extremely viscous liquid/cream used by major biscuit & cookie brands.

Results

The engineering team was completely satisfied with the technical details of the SIVTEK Vibro Separator, SIVTEK Inline Sifter i.e. Low Profile Separator, and SIVTEK Self Cleaning Filter, combining together, assisted leading biscuit manufacturing brands to achieve the perfect quality of ingredients and cream quality.

The SIVTEK Solution-The SIVTEK Vibro Separator and SIVTEK Safety Screening equipment were deployed to improve the sizing of various biscuit ingredients such as flour, fat, salt, milk powder, sugar, additives, and more were used further to mix in the right proportions before building the consistent batch of biscuit dough.

High Product Quality

Better Consumer Loyalty

Low Costs