Committed To Quality, Committed To You

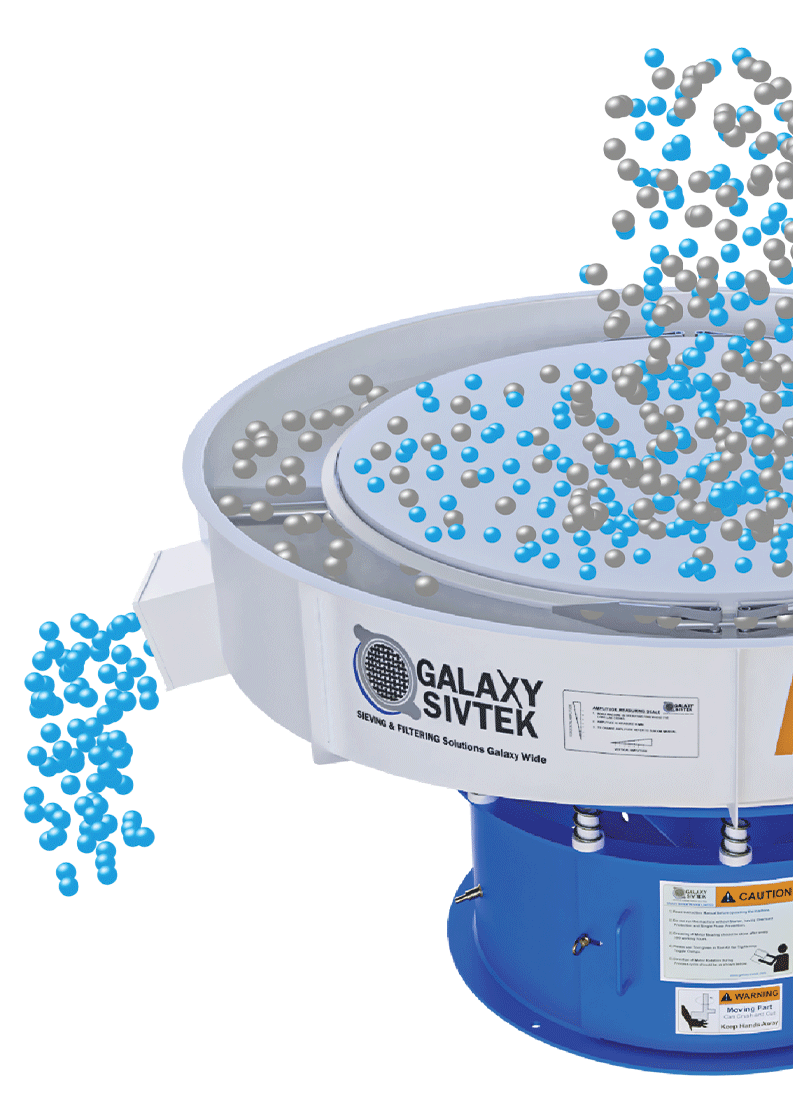

The unique design of the SIVTEK 360° Discharge Separator® makes it one of the best and most efficient industrial liquid filters. The ingenious design of the machine rotates the screening material at a 360° angle, which seamlessly discharges oversized particles. As this inclined screening motion does not allow oversized particles to deposit on the periphery of the screen, it considerably enhances the discharge capacity of the screening process and allows you to fully utilize the capacity of the screening area.

Due to its high discharging capacity without facing any blockages, it provides a longer mesh life.

The machine’s design equally discharges particles on the screen, which optimizes the area usage and increases the throughput.

With its self-cleaning and de-clogging mechanism, SIVTEK 360 can work for elongated hours, without any interruption and provides the best quality finished product.

As the machine consumes lesser power than other machines, it reduces your costs exponentially.

The most impressive property of our product is the 24X7 capacity to continuously process the substance, without taking a break.

The seamless performance of SIVTEK 360° requires little to no supervision which reduces your cost of manpower. It also provides more output in a small period which makes it very cost-efficient.