Committed To Quality, Committed To You

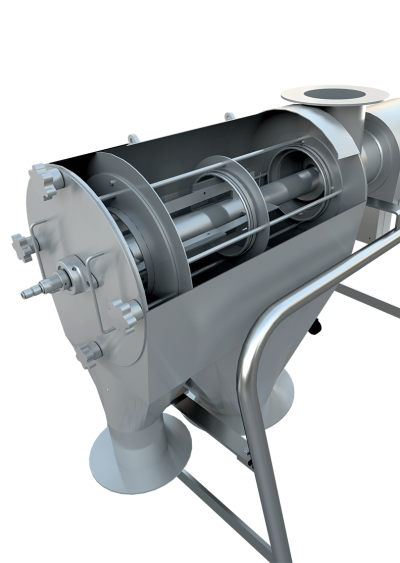

One of the highlights of Roto Sifters’ ingenious design is that it not only assures dust-tight processing, but it can also allow you to process your materials in a vacuum-packed environment if need be. The beater bars on the screener generate a centrifugal force, which propels the screening material against the screen mesh and separates it by particle sizes. Furthermore, the cantilever design of the machine allows you to maintain a hygienic environment while keeping the sound emission to a minimum.

The Roto Sifter is endowed with convenient inspection windows which help to keep an eye on the screening process.

The SIVTEK Roto Sifter is firmly designed to contain the screening material. It increases safety while operating with hazardous substances.

The machine operates with minimal vibrations and keeps the noise level below 80DB.

With multiple options and knobs to disassemble the machine, it is very easy to clean the machine.

The Roto Sifter has a compact design which makes it more flexible and maneuverable.

The numerous knobs on the machine make it easy to remove, dismantle and re-install internal parts. This makes the machine easier to clean and maintain.