Committed To Quality, Committed To You

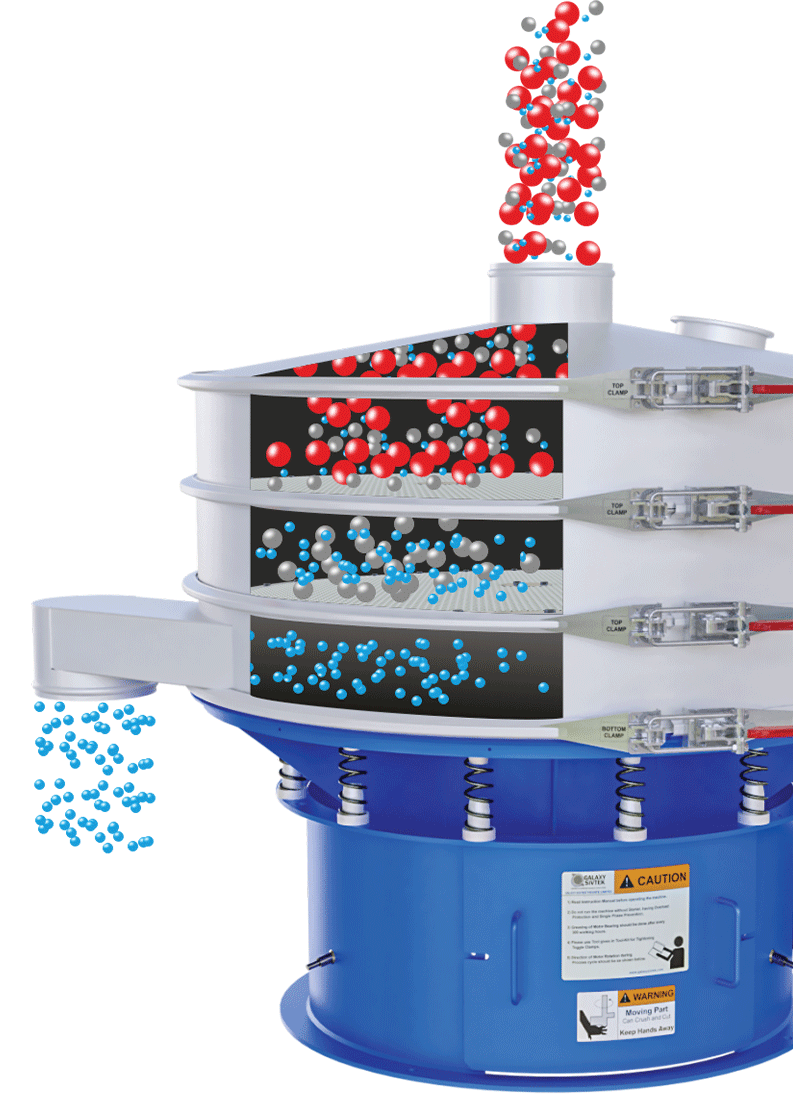

With the help of eccentric weights that are mounted on the upper and lower ends of the motion generator shaft of the machine, Sivtek Vibro Sifter achieves the staggering high-intensity vibrations that it is famous for. The dual weights allow the machine to move in a circular motion, as the lower weights aim to tilt the machine to generate vertical vibrations and the top weights move to distribute the materials across the screen.

Keeping the noise level below 75DB, the SIVTEK Gyro Screener is quieter in comparison to any conventional Vibro sifters.

The machine is designed to be tightly packed so that no contaminants can enter the machine and no particles can leak from the machine.

It is designed to provide high throughput by quickly and efficiently sorting large quantities of materials. By vibrating the screen, particles move across the mesh openings and are separated by their sizes.

The Sivtek Vibro sifter produces very minimal sound while processing, which assures the least amount of noise emission.

The Sivtek Vibro sifter requires little to no maintenance, which highly reduces the expenses.

With the easy mesh changing clamps that are embedded in the machine, you can very conveniently clean the screener and assure pure raw material every time.