VIBRO SIFTER – SANITARY SIVTEK®

Introducing the Vibro Sifter: Precision Screening Solutions for Industry Leaders

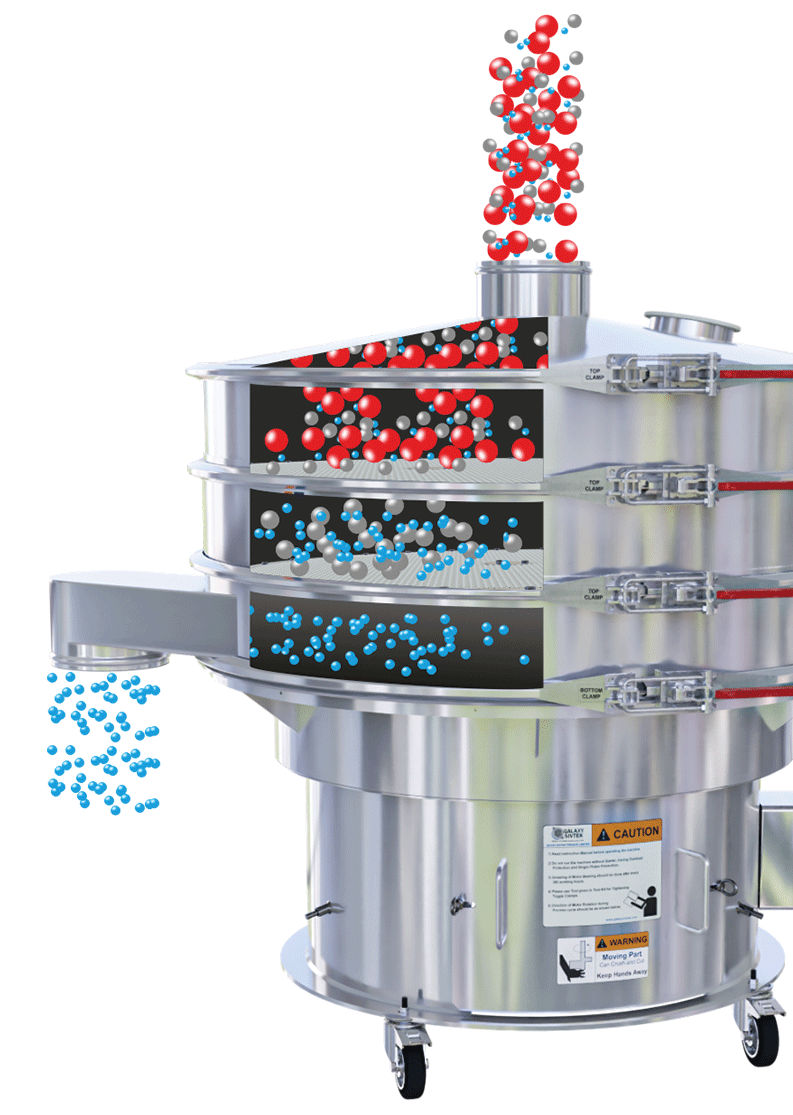

Want to boost your material processing capabilities? This state-of-the-art Vibro Sifter is what your processing line needs. Featured with an exemplary and innovative vibratory screening system, this vibro sifter creates new standards in particle separation and quality control, delivering unmatched precision and efficiency across a wide range of industrial applications.

At the heart of modern processing operations, our industrial vibro sifter is endowed with cutting-edge gyroscopic motion technology that can achieve superior particle separation. From its innovative design that generates optimized vibrational patterns to its gentle product handling that is crucial for maintaining product integrity, this Vibratory Sifter ensures thorough screening results while preventing material degradation.

Whatever your processing requirements may be – be it fine pharmaceutical powders, food ingredients, or chemical compounds – our Vibro Sifter adapts seamlessly to your specific requirements. Owing to its versatile design, the Vibratory Sifter can accommodate multiple mesh configurations, allowing precise separation of particles ranging from microns to millimeters. This flexibility will make the machine an indispensable tool for quality-conscious manufacturers across industries.

Not only does it excel in particle separation, our Vibratory Sifter also offers the highest attainable margins of hygiene. In pharmaceutical manufacturing, our vibratory sifter maintains the strictest hygiene standards while ensuring consistent particle size distribution – critical for maintaining drug efficacy and safety. Food processors rely on our technology to achieve impeccable ingredient quality, whether sieving flour, sugar, or specialty additives. In the chemical industry, our sifters handle everything from aggressive compounds to sensitive materials with unwavering reliability.

What sets our Vibro Sifter apart?

1 – Advanced automatic mesh cleaning system that eliminates blinding and ensures continuous operation

2 – Tool-free design allowing rapid mesh changes and minimal downtime

3 – Energy-efficient operation that reduces operational costs while maximizing throughput

4 – GMP-compliant construction with FDA-approved contact parts

5 – Customizable configurations to match specific process requirements

Owing to its robust construction, coupled with sophisticated vibration control, this industrial Vibro Screen ensures consistent performance even under demanding 24/7 operations. Furthermore, our noise-optimized design creates a better working environment while maintaining superior screening efficiency.

Experience the perfect balance of innovation and reliability with a system that’s engineered to elevate your processing capabilities. From small-batch specialty products to high-volume industrial applications, our Vibro Screen delivers the performance and precision your operation demands.

Contact us today to discover why industry leaders choose us as their trusted Vibro Sifter manufacturer.